Metal Fabrication

What Is Metal Fabrication?

Custom metal fabrication is a vital part of our everyday lives. It’s something we take for granted until you start thinking about how metals are used to make everything from cars, tools, appliances, or even phone cases. We unknowingly rely on metal fabrication processes for survival. Without it, we wouldn’t be able to power the electrical system in homes and businesses and create parts that keep machines running smoothly.

This guide provides you with information about metal fabrication. You will learn about the different types of fabrication processes, technology, and how various metals are fabricated.

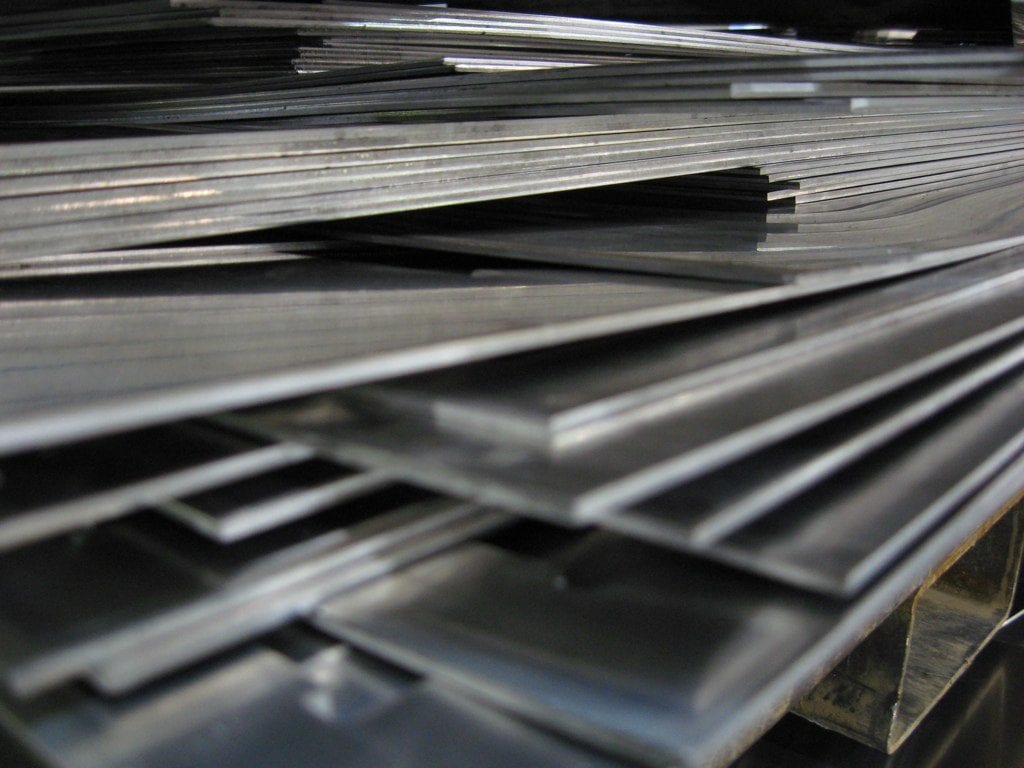

What is sheet metal fabrication?

Metal fabrication is the process of creating metal structures by cutting, bending, and welding pieces of metal. It can be used to create everything from small parts and tools to large structural components and machines. The process typically begins with a design that an engineer or designer draws up.

Once the design is finalized, the individual pieces are fabricated using a variety of machines and tools. Then metal fabricators assemble and test the finished product to ensure it meets all the requirements.

Metal fabrication can be used in a variety of industries, including medical & pharmaceutical, chemical, food & agricultural, manufacturing, and industrial. It offers several benefits, including durability, versatility, and accuracy.

The technology used for metal fabrication

Metal fabrication technology has come a long way in recent years, with advances in CAD software, automation, and machinery. These technologies are now at the forefront of the fabrication process, making it easier and more efficient than ever before.

CAD software allows for precise measurements and drawings, which is essential for accurate metal fabrication. Automation speeds up the process by reducing the need for manual labor, and machinery such as our Protem machines can create perfectly consistent results.

Let’s go into more detail on each of these technologies:

- Computer-aided Design Software (CAD): CAD is a type of software that engineers and designers use to create 3D models and drawings of metal fabrication projects. This software system allows for quick updates and changes to the design. CAD software makes it possible to quickly create, edit, and iterate on designs. This allows for more efficient and accurate product development and can save time and money in the design process.

- Machinery: Machinery is a critical part of any metal fabrication operation. Many types of machines can be used in metal fabrication, each with unique capabilities and advantages. For example, we have:

- Laser technology: It is commonly used in metal fabrication for cutting and welding applications. Lasers can provide high accuracy and repeatability, making them ideal for use in production environments. Laser systems can be automated, further increasing efficiency and throughput.

- Plasma cutting: It is another common technique used in metal fabrication. Plasma cutting uses a stream of ionized gas to cut through metals. Plasma cutting can be used to cut thin and thick materials, making it a versatile option for many applications.

- Waterjet cutting: It is a third option for metal fabrication that uses high-pressure water to cut through materials. Waterjet cutting can be used to cut a variety of materials, including metals, stone, and glass. Waterjet cutting systems can be quite large and expensive, making them most suitable for industrial applications.

- Automation: The use of automation in fabrication has revolutionized the process in recent years. Machines are now being produced with programming capabilities that automatically allow them to complete projects to specifications with minimal human involvement.

This has dramatically increased industry efficiency and productivity, reduced errors, and increased safety. Automation has also made it possible to fabricate more complex products that would otherwise be too difficult or expensive to produce manually. This has opened up new opportunities for businesses in the fabrication industry and provided consumers with access to a broader range of products.

Types of metal fabrication processes

Metal fabricators use various methods in metal fabrication, and the choice of method will often depend on the desired final product. So what is the metal fabrication process?

Here is a brief overview of some of the most common methods:

| Welding | Welding is a process whereby two pieces of metal are joined together by heating them to a melting point and then cooling them so that they bond together. |

|---|---|

| Casting | his process involves pouring molten metal into a mold to create the desired shape. It is often used for large or complex shapes that would be difficult to produce using other methods. |

| Cutting | This process involves using a cutting tool to remove excess metal from a workpiece. It can be used to create complex shapes or trim a piece to the desired size. |

| Forging | This process involves using hammers or presses to shape metal by striking it. It is often used to create solid, durable parts that withstand high stress. |

| Extrusion | his process involves forcing metal through a die to create the desired shape. It is often used for parts that need to be strong and lightweight, such as tubing or piping. |

| Punching | This process involves using a punch to cut holes or shapes in metal. It is often used to create openings for fasteners or other components. Punching is a quick and easy process. |

| Milling | This process involves using a milling machine to remove excess metal from a workpiece. It can be used to create complex shapes or trim a piece to the desired size. Milling is a relatively quick and easy process. |

| Drilling | This process involves using a drill to create holes in metal. It is often used to create openings for fasteners or other components. |

| Stamping | This process involves using a stamping press to cut shapes or holes in metal. It is often used to create openings for fasteners or other components. |

| Shearing | This process involves using a shearing machine to cut metal into the desired length. It is often used for parts that need to be strong and lightweight, such as tubing or piping. |

| Machining | This process involves using machine tools to remove excess metal from a workpiece. It can be used to create complex shapes or trim a piece to the desired size. |

| Folding | This process involves using a folding machine to fold metal into the desired shape. |

How different metals are fabricated

Different metals have different properties, and as a result, they require different fabrication methods. Let’s take a look at some of the most common metals and how they’re fabricated.

- Aluminum is a lightweight and durable metal often used in the manufacturing industry. It can be fabricated using several methods, including casting, forging, stamping, and machining.

- Steel is a strong metal often used in construction. It can be fabricated using several methods, including casting, forging, stamping, and machining.

- Copper is a soft metal often used in electrical applications. It can be fabricated using several methods, including casting, stamping, and machining.

- Titanium is a strong metal often used in the aerospace industry. It can be fabricated using several methods, including casting, forging, stamping, and machining.

Final thoughts: Metal fabrication

Metal fabrication is a process that’s integral to many industries. It is a critical process in constructing buildings, bridges, machines, and other infrastructure. It also helps us create products and components essential to our everyday lives.

For over 25 years, 43Forty has provided quality metal fabrication services to our clients from various industries. We have the experience and expertise to get the job done right, on time, and within budget. Contact us today if you need a custom metal fabrication for your next project. We would be happy to discuss your needs and provide a quote for our services.